ūóŻ║1Īó╠ž╩Ōę¬Ū¾┐╔░┤ė├æ¶łD╝łųŲū„��Ż¼Ę©╠mś╦(bi©Īo)£╩(zh©│n)▓╔ė├GB/T9115.1-2000����Ż¼┐╔▀x┼õŻ©GBĪóJB���ĪóHG���ĪóCB��ĪóANSI�ĪóDIN�ĪóBSEN�����ĪóNF����ĪóENĪóJIS����Īó

ISOĄ╚Ż®Ę©╠mś╦(bi©Īo)£╩(zh©│n)╔·«a(ch©Żn)ĪŻ2��Īóæę┐šĮo╦«╩╣ė├DN200ęį╔Ž«a(ch©Żn)ŲĘ����Ż¼╣▄Ą└▒žĒÜėą╣╠Č©ų¦ō╬╗“╣╠Č©═ą╝▄Ż¼Ę±ät«a(ch©Żn)ŲĘæ¬(y©®ng)░▓čbĘ└└Ł├ōčbų├����ĪŻ

3��Īóė├æ¶╩╣ė├Ž─zĮėŅ^�����Ż¼ī”(du©¼)æ¬(y©®ng)Ę©╠mæ¬(y©®ng)╩ŪķyķTĘ©╠m╗“Ę¹║ŽGB/T9115.1-2000Ę©╠m���ĪŻ

Notes:

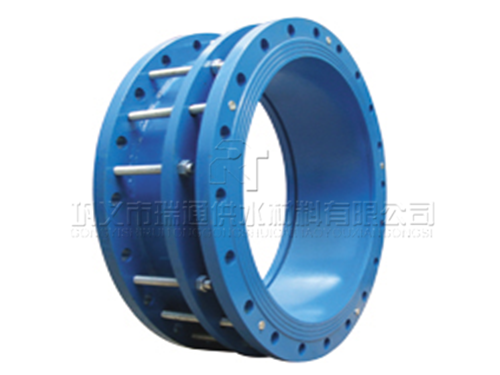

1. For OEM orders with special requirement, rubber joints can be made according

to customers' drawings. Generally, flange standard is GB/T9115.1-2000, other GB,

JB, HG, CB, ANSI, DIN, BSEN, NF, EN, JIS, ISO flanges are also available upon

request.2.When rubber joints size above DN200 are used for overhead water supply

system, the pipes must be equipped with fixed supports or fixed brackets,

otherwise control units shall be installed on rubber joints.

3.Matching

flanges of rubber joints shall be valve flanges or GB/T9115.1(RF) flanges.

|